Rotary pump is a common volumetric pump used for transporting liquids or compressed gases. It has a unique structure and working principle, and is widely used in industrial fields and daily life. This article will introduce rotary pumps from several aspects, including structure, working principle, function, and application scope.

1. Structural characteristics of rotary pump

A rotary pump is mainly composed of a pump body, rotor, bearings, and sealing device.

Pump body: usually made of stainless steel 304, 316, with good corrosion resistance and durability. The design shape inside the pump body can be adjusted according to the characteristics of the liquid or gas to improve the efficiency of the pump.

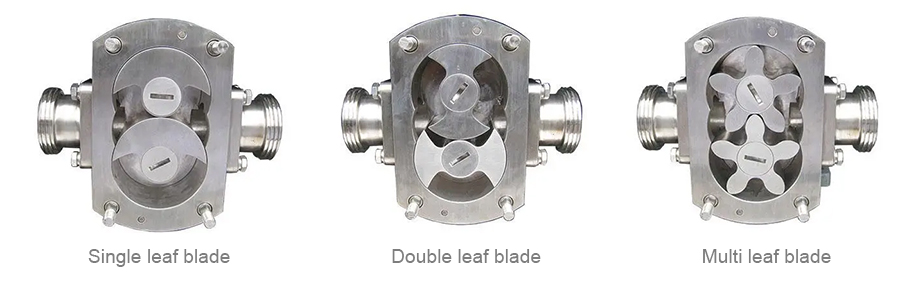

Rotor: The rotor is the core component of a rotary pump, usually made of metal materials. The rotor is composed of multiple blades and can be driven to rotate by a motor or other power source, allowing liquids or gases to be drawn in and out.

Bearings: The bearings of rotary pumps are usually made of high wear-resistant materials, which can support and maintain the stable operation of the rotor.

Sealing device: There are various types of sealing devices for rotary pumps, which can effectively prevent leakage and ensure the normal operation of the pump.

2. Working principle of rotary pump

The working principle of a rotary pump is based on centrifugal force and volume effect.

Inhalation process: When the rotor rotates, the blades of the rotor generate centrifugal force through rotation, causing liquid or gas to be sucked in from the feed inlet. The volume inside the rotor gradually increases, forming a negative pressure zone that draws liquid or gas into the pump body.

Discharge process: As the rotor continues to rotate, the volume gradually decreases, forming a positive pressure zone that pushes liquid or gas out through the discharge port.

3. The rotary pump has the following main functions:

Liquid or gas transportation: rotor pumps are widely used to transport various liquids or gases, including water, oil, lotion, solvents, corrosive media, etc. Has high conveying capacity and pressure.

Provide stable flow: Rotary pumps provide stable flow through rotational motion and can be adjusted as needed. This is very important for processes that require precise flow control.

Low noise and vibration: The structure and working principle of the rotary pump make it have the characteristics of low noise and vibration, which can reduce interference with the environment and equipment.

Energy saving and efficient: Some advanced rotary pumps adopt energy-saving designs and optimized fluid dynamics structures, which can improve pump efficiency and reduce energy consumption.

4. Rotary pumps have a wide range of applications in many fields, including but not limited to the following areas:

In the industrial field, rotary pumps are widely used in industries such as chemical, petroleum, pharmaceutical, food processing, wine making, and papermaking to transport various liquids or gases, such as acid and alkali solutions, oil products, raw material medicines, beverages, and pulp.

In the field of agriculture, rotary pumps are commonly used in agricultural engineering such as irrigation systems, farmland drainage, and pesticide spraying to provide water sources, boost pressure, and transport liquid products.

In the construction industry, rotary pumps are commonly used in applications such as water supply systems, heating systems, pressure boosting, and water circulation to provide stable water supply and hydraulic support for buildings.

In the field of daily life, the application of rotary pumps in residential life cannot be ignored, such as household hot water circulation, heating systems, pond drainage, and garage sewage.

Contact: NEIL

Phone: 86-18205509969

E-mail: 18205509969@139.com

Add: 118, Building 3, Tianrun City Phase II, Tianchang City, Anhui Province. China