1. Determination of the pressure of the progressing cavity pump

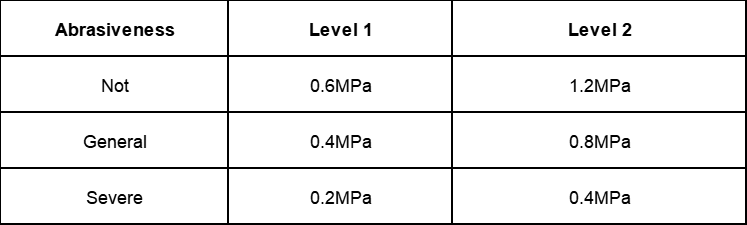

The maximum output pressure of a progressing cavity pump is determined according to the number of bushing stages, i.e. the number of leads of the bushing:

Level 1: High working pressure of 0.6 MPa;

Level 2: High working pressure of 1.2 MPa;

Due to the different conditions of the conveying medium, for the medium with severe abrasion, please refer to Table 1 to select the number of bushing stages.

Table 1: The number of bushing stages is selected according to the abrasiveness of the medium

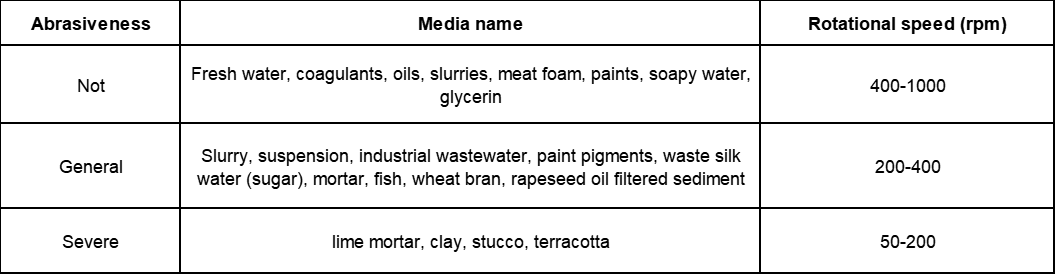

2. Selection of progressing cavity pump speed:

Due to its structural characteristics, most of the progressing cavity pumps are used to convey liquids with higher viscosity and liquids containing particles, so the selection of its rotation rate is very critical.

Table 2: Select the pump speed according to the abrasive nature of the medium

*Special examples of the specific media to be conveyed and their wear characteristics are given in the table, please note that the characteristics of the medium vary with its concentration and temperature.

*When the size of the pump is large, the speed should be lower.

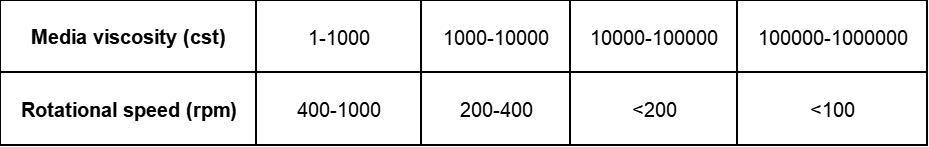

Table 3: Select the pump speed according to the viscosity of the medium

* When choosing the speed, it is also necessary to rely on experience, because some other factors also affect the choice of speed, and it is good to negotiate with the manufacturer while determining the above values.

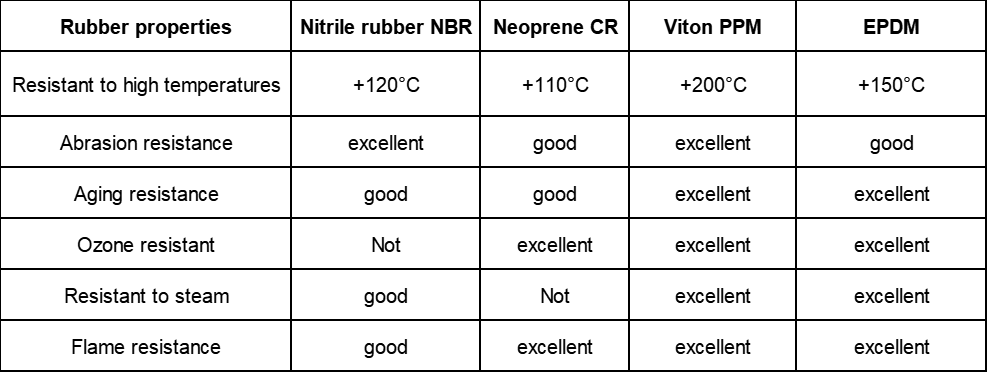

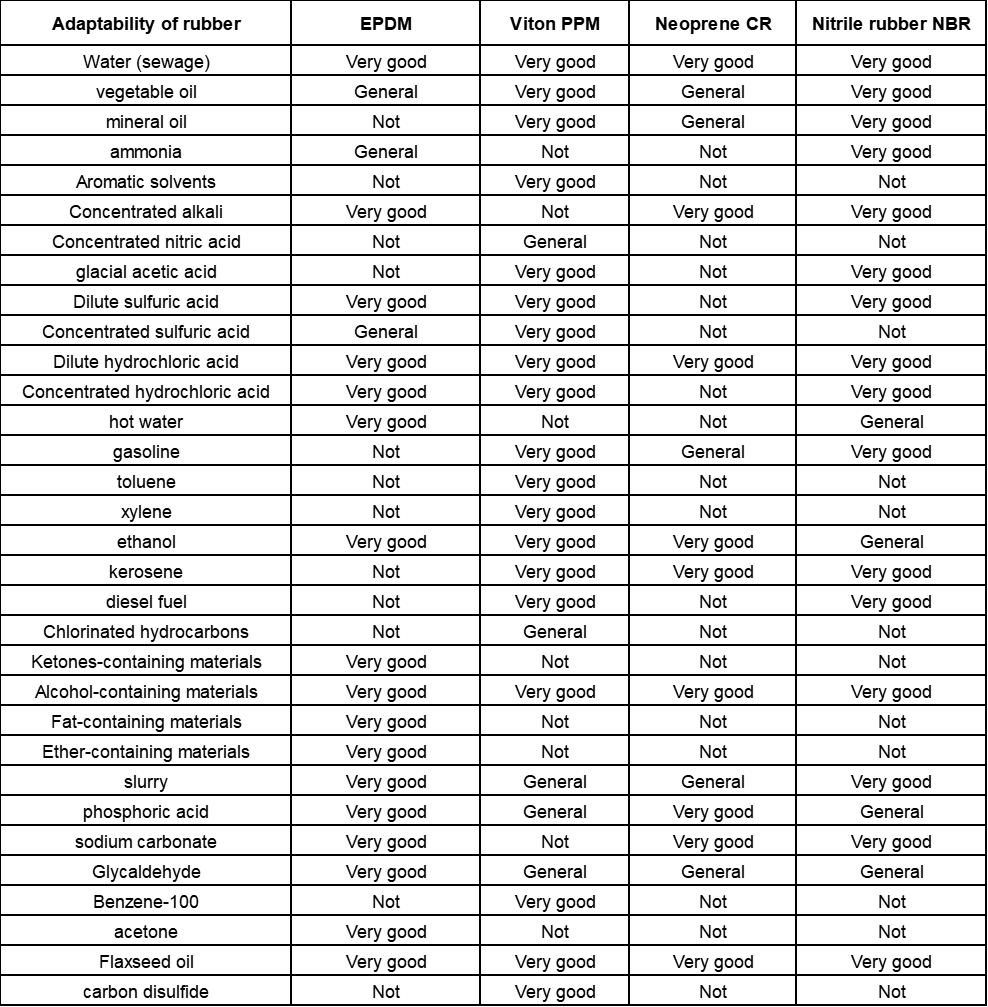

3. Selection of rubber material for progressing cavity pump bushing:

The bushing of the progressing cavity pump is a rubber product, which is also a progressing cavity pumpA wearing part, its selection is good or bad, directly affects the life of the bushing, generally under normal circumstances, the life of the bushing is 3-6 months, if the selection is improper, the bushing may fall off from the steel pipe or rubber block. Therefore, we are required to have an understanding of the basic characteristics of rubber and the adaptability of rubber to various different media, and list Table 4 and Table 5 based on our experience.

Table 4: Basic characteristics of rubber

Table 5: Rubber is commonly used in the bushing of progressing cavity pump

4. Material Combination Selection

Conveying media with different properties requires different combinations of materials.

5. Performance Table

Generally, the performance table or characteristic curve of the progressing cavity pump is the data when 20C clean water is used as the medium (viscosity is 1cst), and the flow rate and shaft power are different for conveying different viscosities.

6. Shaft seal

According to the needs and the conveying medium, mechanical seals and packing seals can be used, and the two structures are interchangeable.

7. Pump driving mode

Because the screw pump is a low-speed pump, there are many driving modes of the pump, generally including low-speed motor direct connection (6-stage, 8-stage), gear reducer motor drive, stepless variable speed motor drive, etc.

Contact: NEIL

Phone: 86-18205509969

E-mail: 18205509969@139.com

Add: 118, Building 3, Tianrun City Phase II, Tianchang City, Anhui Province. China