According to the comparative analysis and selection suggestions of stainless steel magnetic pump and stainless steel centrifugal pump, a structured presentation method is adopted:

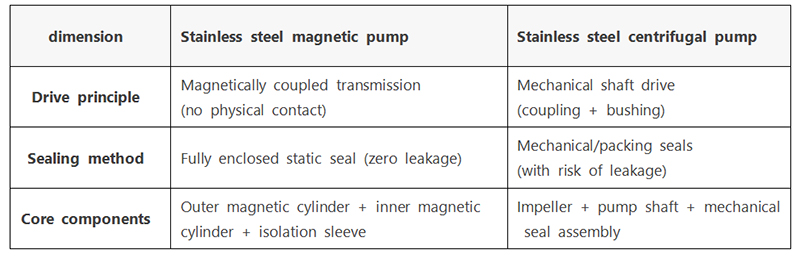

1. Comparison of core structure differences

2. Comparison of performance advantages and disadvantages

Absolute leak-proof: no shaft seal design, completely eliminate leakage, suitable for highly toxic/high-risk media (such as hydrofluoric acid, chloromethane, etc.)

Low maintenance costs: No mechanical seal wear and less frequent downtime.

Corrosion resistance strengthening: 316L/904L/Hastelloy and other materials can be customized.

Ultra-clean environment adaptation: no lubricating oil pollution, suitable for semiconductor and pharmaceutical GMP scenarios

Efficiency loss: Magnetic vortex results in 10-15% higher energy consumption than centrifugal pumps.

Temperature resistance limit: long-term working temperature is generally ≤ 350°C (high temperature will degauss).

The cost is higher: the price is about 1.5-2 times that of centrifugal pumps with the same parameters.

Viscosity-sensitive: The efficiency drops dramatically at the viscosity of the medium > 200cP.

Stainless steel centrifugal pump

High efficiency and energy saving: 75-92% typical efficiency, significant advantages in large flow conditions

Strong pressure resistance: the single-stage head can reach more than 200 meters, which is suitable for high-pressure systems

Economical and practical: low acquisition costs and a high degree of standardization of spare parts

Universal medium: It can handle liquids containing trace particles (wear-resistant impellers are required).

Leakage risk: The probability of failure of mechanical seals > 3‰/year (according to API 682 standard statistics).

Frequent maintenance: Sealing components need to be replaced every 4,000-8,000 hours.

Risk of contamination: Lubricating oil may penetrate the medium and affect the purity of the product.

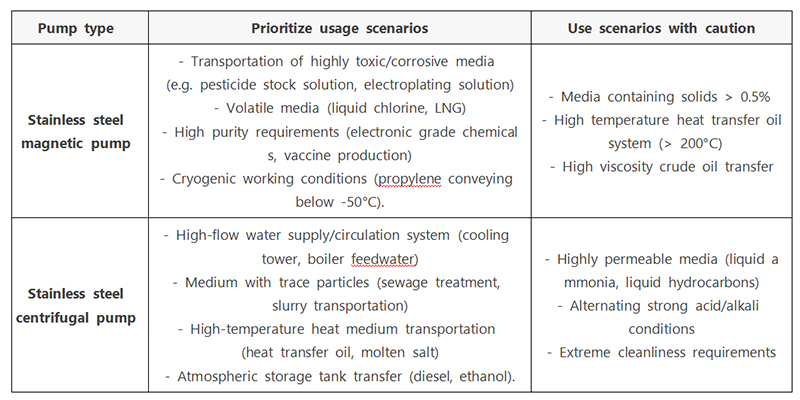

3. Guide to typical application scenarios

Fourth, the selection decision tree

The medium is highly dangerous→ choose a magnetic pump

Limited budget + media safety → Centrifugal pump + double-acting mechanical seal

Working conditions with particulate matter → Centrifugal pump + open impeller design

System Requirements: Zero Contamination → Magnetic pump + polished to Ra0.4μm

Frequent start and stop are required→ centrifugal pump + frequency conversion control (to avoid magnetic pump demagnetization).

5. Industry application data reference

Magnetic pump: The penetration rate in the field of fine chemicals is 68%, and the lithium battery electrolyte production line is standard

Centrifugal pump: accounting for 57% of the total pump equipment in the petrochemical industry, the main pump type of oil refining unit

It is recommended to combine the specific media characteristics, operating parameters (temperature/pressure/viscosity) and safety specifications (e.g. API 685/ISO 2858) for final selection.

Contact: NEIL

Phone: 86-18205509969

E-mail: 18205509969@139.com

Add: 118, Building 3, Tianrun City Phase II, Tianchang City, Anhui Province. China