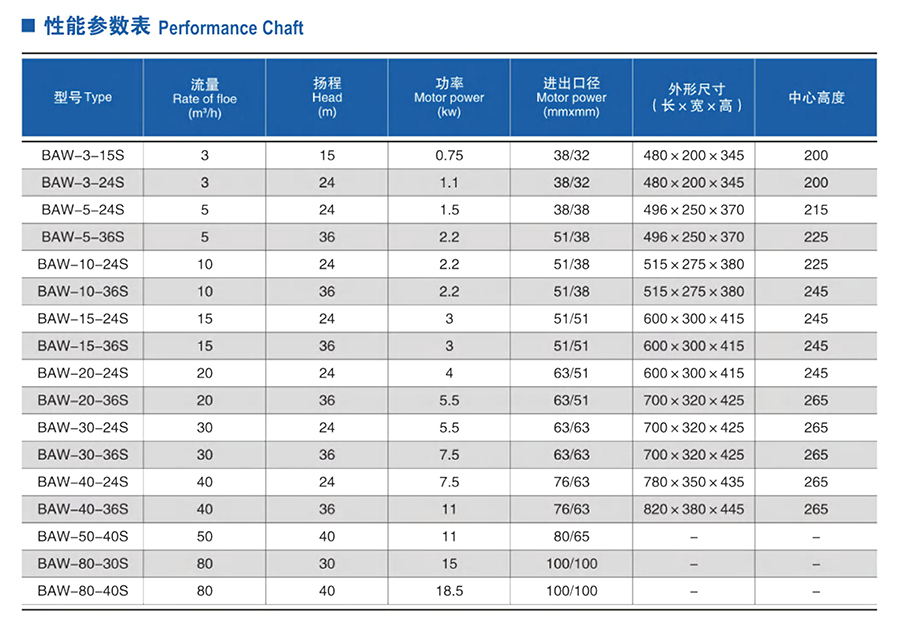

Model: BAW5-24

Pump inlet diameter: 38 mm

Pump outlet diameter: 38 mm

Flow rate: 5 m³/h

Head: 24 m

Power: 1.5 KW

Material: SS304/SS316

We can provide pump selection for free.

Please send the liquid name, temperature, density, viscosity, and other requirements.

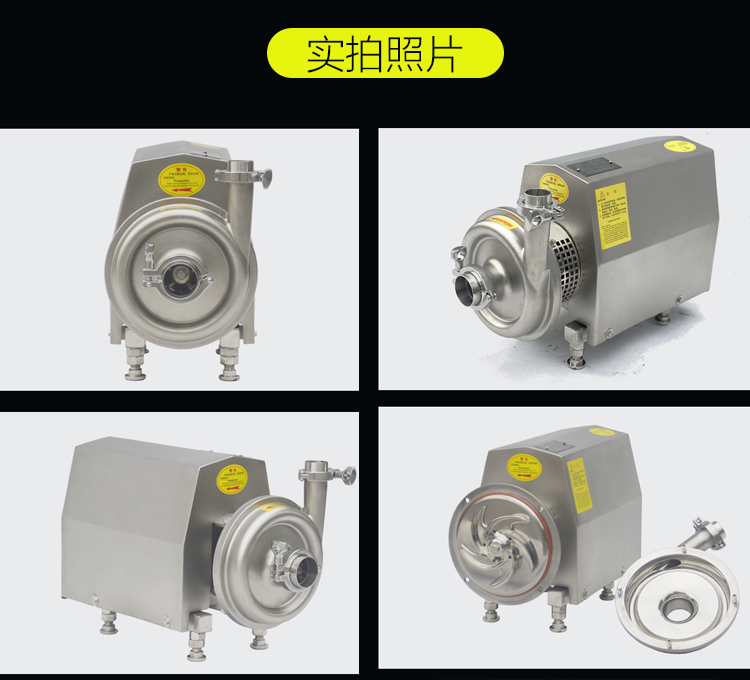

BAW sanitary centrifugal pump is a single suction, single-stage, centrifugal sanitary pump suitable for conveying various liquids such as milk, beverages, and alcohol. It is an indispensable conveying equipment in industries such as food, chemical, and pharmaceutical. The pump body, pump cover, impeller and other parts in contact with the material are all made of 304 or 316 stainless steel, with a maximum temperature of around 150 ℃. Among them, high lift pumps are particularly suitable for applications in systems with high resistance such as tubular sterilization, yogurt holding equipment, CIP cleaning, etc.

Instructions for using BAW sanitary centrifugal pump:

When installing centrifugal sanitary equipment, it is best to position the pump below the suction liquid level (if the pump is installed above the suction liquid level, a tank pump should be used before starting the pump). Before use, check whether the rotation direction of the impeller is correct; Is the nut of the pump inlet and outlet pipe joint tightened; The sealing ring between the pump cover and the pump body is well padded. Steam disinfection should be applied to the parts in contact with materials before use to ensure food hygiene.

A butterfly valve should be installed at the outlet of the pump to control the flow rate. Do not operate under overload conditions for a long time to avoid damaging the motor.

The pump should be immediately cleaned with CIP after use to prevent material adhesion. If CIP is not available, manual cleaning is required. When cleaning, hot water can be used first, then disassembled, and all parts of the pump that come into contact with the material can be brushed with a brush. Then rinse with clean water and install them in order.

If material is found dripping on the ground behind the pump casing during use, it indicates a leakage at the shaft seal. At this point, the mechanical seal device on the shaft can be checked. If it is severely worn or the seal is damaged, it should be replaced or ground before use.

Contact: NEIL

Phone: 86-18205509969

E-mail: 18205509969@139.com

Add: 118, Building 3, Tianrun City Phase II, Tianchang City, Anhui Province. China