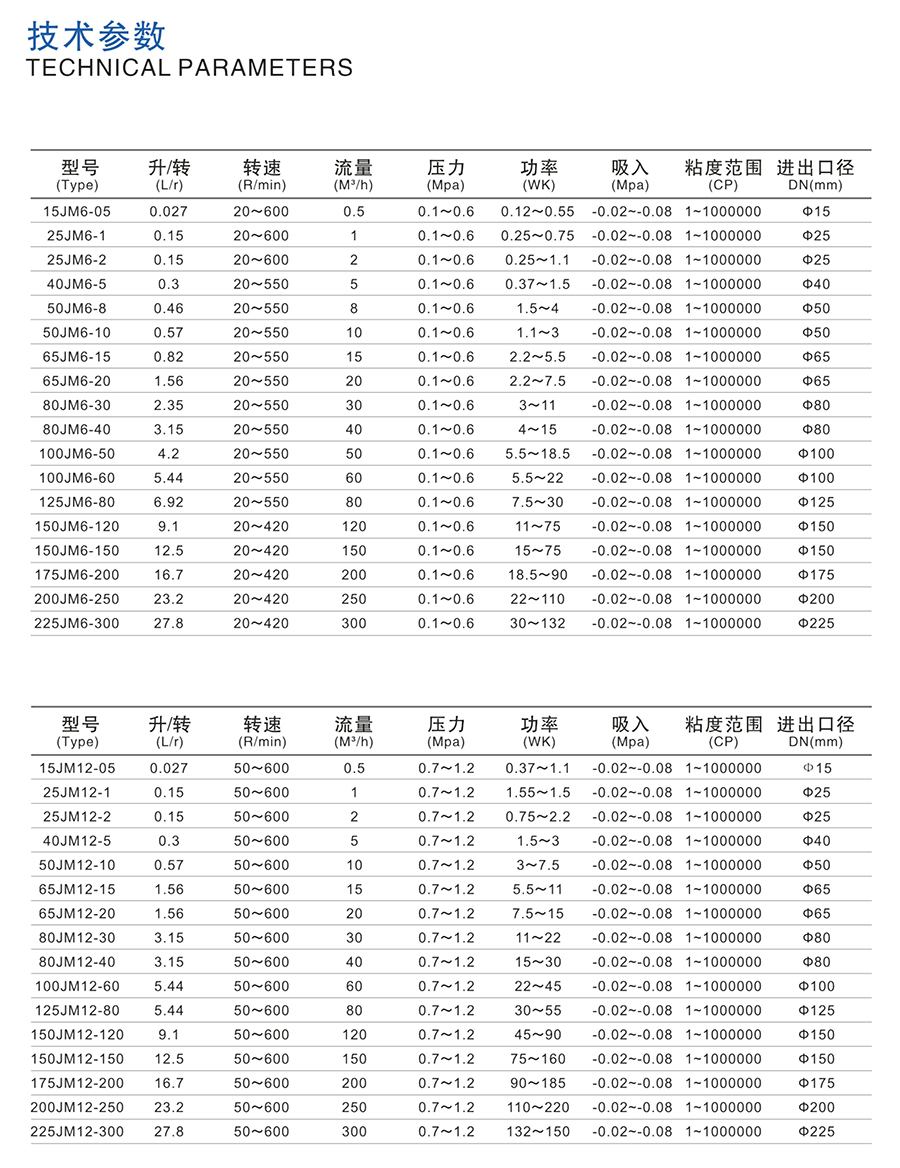

Displacement: positive displacement pump, flow rate up to 400m³/H

Pressure: The pressure can reach 1.2Mpa.

Self-priming: suction vacuum up to -0.095Mpa

Efficiency: up to 90%

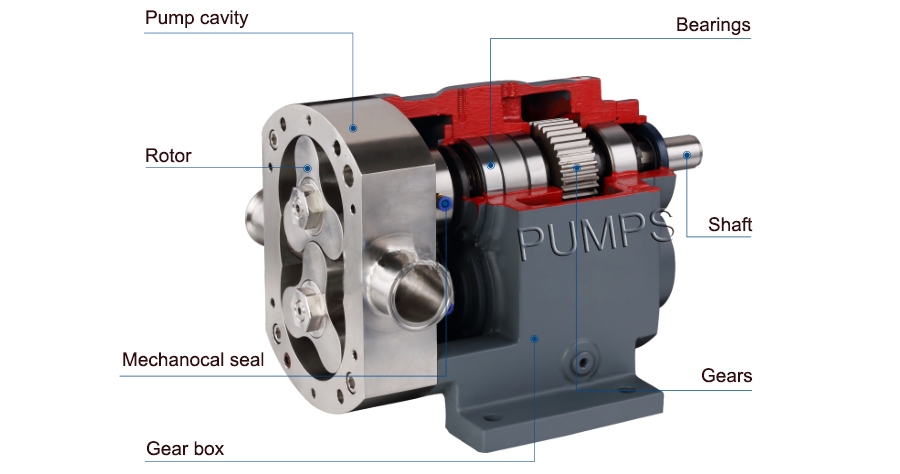

Friction-free: There is a certain gap between the rotor and the rotor, between the rotor and the pump body, no friction, long service life.

ZOOANY rotary lobe pumps are widely used in the food industry. mainly because of the following characteristics:

■High sanitation: The wetted parts are manufactured in stainless steel 316 or 316L.

■High smoothness: surface roughness is below 0.8 μm, confirming to 3A, EHEDG, FDA standard.

■Meet CIP and SIP requirements.

■Simple disassembly and asembly, easy maintenance and few wearing parts.

■Low speed, low shear, no damage to the pumped products.

■Gap is kept between the rotor and the rotor, the rotor and the pump body. No friction, long service life.

■AII main parts are processed by CNC, which have high precision.

■Simple assembly and disassembly, easy maintenance and cleaning, and few wearing parts.

■Energy saving, low failure rate, reliable sealing and low noise.

■Pump flow can be adjusted at will with VFD controlled, and it can be used as a metering pump.

■Pump connection types can be flange, screw, clamp type, etc.

■The transportable medium viscosity is upto1 .5 million cp, and the slurry with a solid content upto 70%.

■It can transport three-phase mixture materials such as vapor, liquid and solid.

Contact: NEIL

Phone: 86-18205509969

E-mail: 18205509969@139.com

Add: 118, Building 3, Tianrun City Phase II, Tianchang City, Anhui Province. China