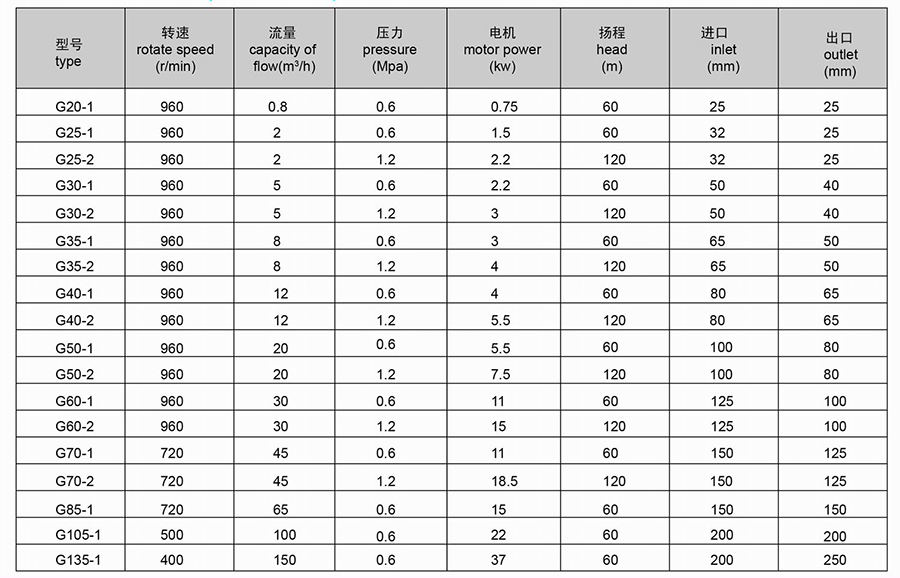

Model: G30-1

Pump inlet diameter: 50 mm

Pump outlet diameter: 40 mm

Flow rate: 5 m³/h

Head: 60 m

Power: 2.2 KW

Material: Cast iron/SS304/SS316

We can provide pump selection for free.

Please send the liquid name, temperature, density, viscosity, and other requirements.

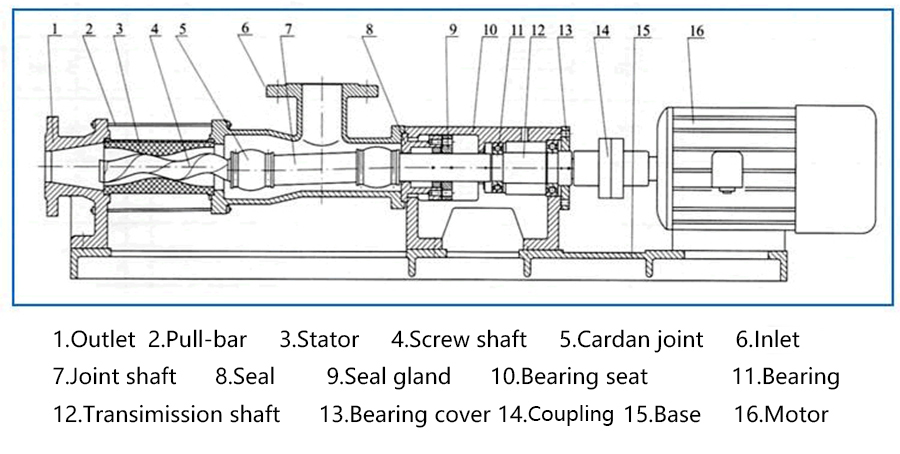

G type Single screw pump belongs to rotary displacement pump, which relies on the mutual engagement of screw and liner to produce volume changes in the suction and discharge chambers to transport liquids. It is a closed screw pump with internal meshing, and the main working components consist of a liner (stator) with a double headed spiral cavity and a single headed spiral screw (rotor) that meshes with it inside the stator cavity. When the input shaft drives the rotor to rotate around the center of the stator through the universal joint, the stator rotor pair continuously meshes to form a sealed chamber. These sealed chambers move at a constant speed in the axial direction, conveying the medium from the suction end to the discharge end through the stator rotor pair. The medium sucked into the sealed chamber flows through the stator without being stirred or damaged.

Product advantages

·Continuous low pulsation conveying, unaffected by pressure and viscosity fluctuations.

·Widely applicable, capable of conveying both flowing and non flowing materials.

·The medium will not be stirred, squeezed or sheared during the pumping process.

·High efficiency, the conveying capacity is proportional to the speed, and the conveying capacity can be adjusted by frequency conversion.

·Most liquids can be pumped with minimal agitation and pulsation.

·Easy to maintain and repair, with high-voltage transmission capability.

Scope of application

·Petroleum industry: heavy oil transportation, oil and gas mixed transportation, oil-water separation, and waste oil recovery systems.

·Chemical and pharmaceutical industries: various pastes, emulsions, suspensions, etc.

·Environmental engineering: various sewage transportation, dewatering sludge transportation, metering and dosing of coagulants and their chemical agents, etc.

·Mineral engineering: production equipment for titanium dioxide, kaolin, calcium carbonate, etc.

·Food industry: dairy products, fruit juice, puree, vegetable sauce, beer, etc.

·Paper industry: raw material equipment, pulp making, and wastewater treatment, etc.

Note: 1. The test data in the performance table is based on water at 20 ℃ as the medium, with a viscosity of 1mm2/s.

2. When the pump transports medium with high viscosity or particles, it depends on the properties of the medium. The speed of the pump is different.

3. When the pump delivers different abrasive media, the pump speed is also different.

Contact: NEIL

Phone: 86-18205509969

E-mail: 18205509969@139.com

Add: 118, Building 3, Tianrun City Phase II, Tianchang City, Anhui Province. China