FJX evaporative forced circulation pump uses the horizontal thrust along the pump shaft generated by the rotation of the impeller to work, so it is also called a horizontal axial flow pump. It is mainly used in evaporation, concentration and cooling in diaphragm caustic soda, phosphoric acid, vacuum salt, lactic acid, calcium lactate, alumina, titanium dioxide, calcium chloride, ammonium chloride, sodium chlorate, sugar, molten salt, papermaking, wastewater and other industries. Therefore, it can also be called axial flow evaporation crystallization circulating pump.

1. the working principle

FJX evaporation forced circulation pump does not rely on the centrifugal force of the impeller on the liquid, but uses the thrust of the rotating impeller blades to make the conveyed liquid flow in the direction of the pump shaft. When the pump shaft is driven and rotated by the motor, because the blades have a certain helix angle with the axis of the pump shaft, a thrust (or lift) is generated on the liquid, and the liquid is pushed out and discharged along the discharge pipe. When the liquid is pushed out, a local vacuum is formed in the original position, and the liquid from the outside is sucked into the impeller along the inlet pipe under atmospheric pressure. As long as the impeller is constantly rotating, the pump is able to continuously draw in and out liquid.

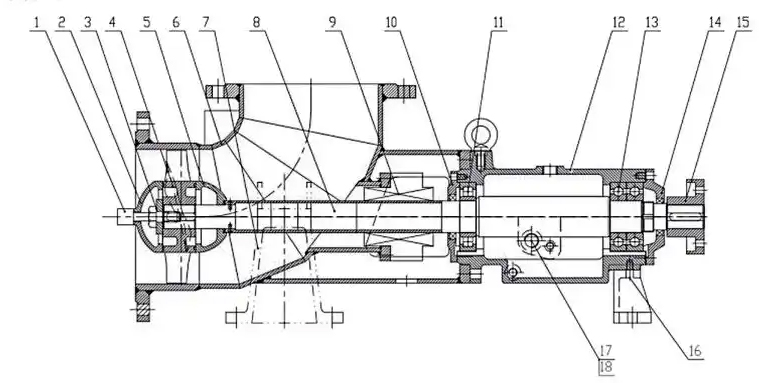

2. Schematic diagram of the structure

3. Structural characteristics

3.1 Good cavitation resistance: suitable for low-level evaporators, which can reduce the investment of evaporation plants.

3.2 High efficiency and wide efficiency area: two methods of changing the installation angle of the blade and changing the speed are used to meet the user's requirements for flow and head, and the operation station of the pump is in the high-efficiency area of the pump, and the energy-saving effect is significant.

3.3 Slow type: the pump runs smoothly; The flow parts are light in wear and have a long service life; The crystal breakage is low, which is suitable for the evaporation crystallization process.

3.4 Cantilever rotor: compared with the double-support type, the number of shaft seals is halved, the pump is light in weight, small in size, and easy to maintain.

3.5 Pump body center support: Compared with the pump body foot support type, the rotor heat is better neutral.

3.6 Rear door structure: the rotor can be withdrawn without disassembling the inlet and outlet flanges of the pump body, which is convenient and fast for maintenance.

3.7 Advanced shaft seal: with cartridge machine seal, the service life is 6-12 months; Sealed with a new type of liquid-blocking packing, the packing is sealed for 3-6 months.

3.8 Evaporator without expansion joint: It can be used for elastic pump base or suspended pump, with reliable thermal compensation and reduced evaporator investment.

3.9 High reliability of the whole machine: high strength of the pump shaft, large bearing capacity, water-cooled jacket for the bearing seat, long life of the shaft seal, good material performance, to ensure the long-term operation of a single pump.

4. the description of the use

This series of axial flow pumps can be widely used in evaporation, crystallization, chemical reaction and other processes in chemical, non-ferrous metal, salt production, light industry and other industries, and its typical application range is as follows:

Phosphate fertilizer plant: forced circulation of wet phosphoric acid concentrator, ammonium phosphate slurry concentrator medium.

Bayer alumina plant: Forced circulation of sodium aluminate liquid evaporator medium.

Diaphragm caustic soda plant: forced circulation of caustic soda evaporator medium containing NaCl.

Vacuum salt production:Forced circulation pump for NaCl evaporation crystallizer media.

Hydrometallurgical plant: forced circulation of evaporation crystallizer media such as copper sulfate and nickel sulfate.

Soda refinery: ammonium chloride process cold treatment crystallizer, salting out crystallizer ammonia mother liquor forced circulation.

Soda ash plant: ammonium distillation waste liquid recovery process, forced circulation of CaCl2 evaporator medium.

Paper mills: Forced circulation of the night concentrator medium.

Power plants: flue gas desulfurization, forced circulation of ammonium sulfate evaporation crystallizer medium in coking plants and chemical fiber plants.

Light industry: forced circulation of alcohol concentration, citric acid evaporation, sugar evaporation and other station media.

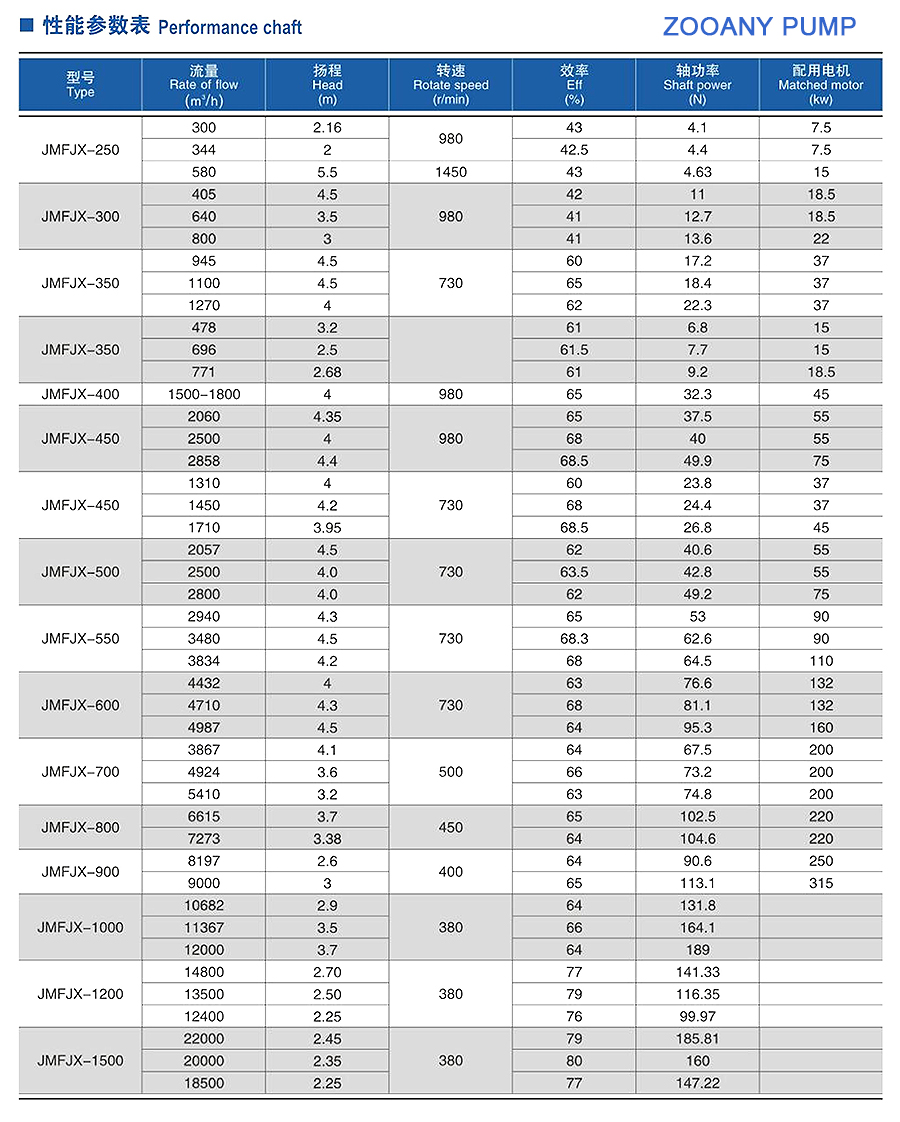

5. Performance parameter table

Contact: NEIL

Phone: 86-18205509969

E-mail: 18205509969@139.com

Add: 118, Building 3, Tianrun City Phase II, Tianchang City, Anhui Province. China