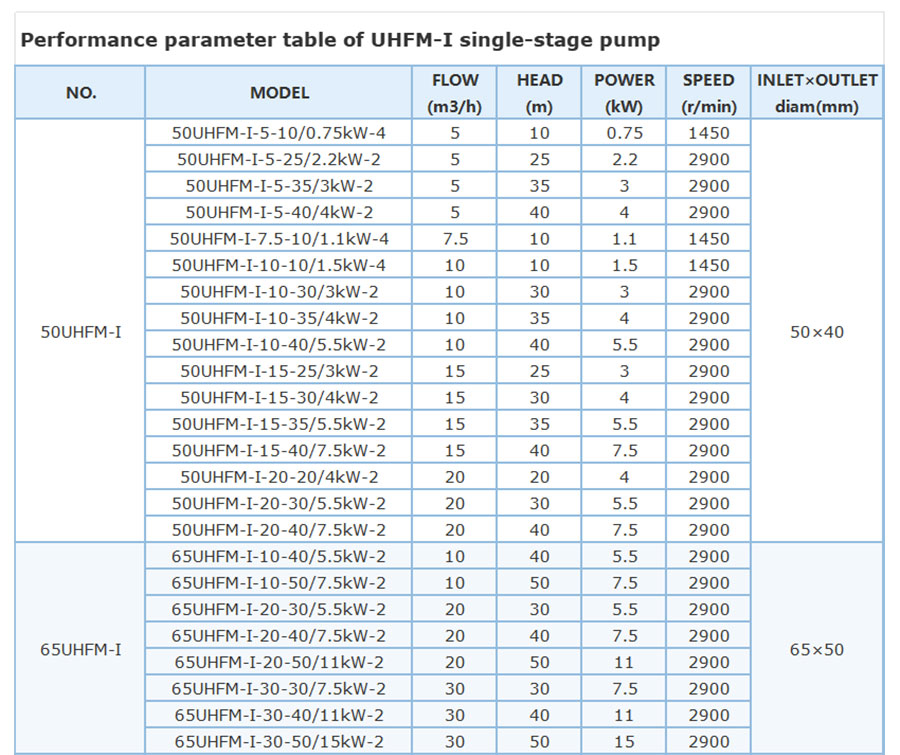

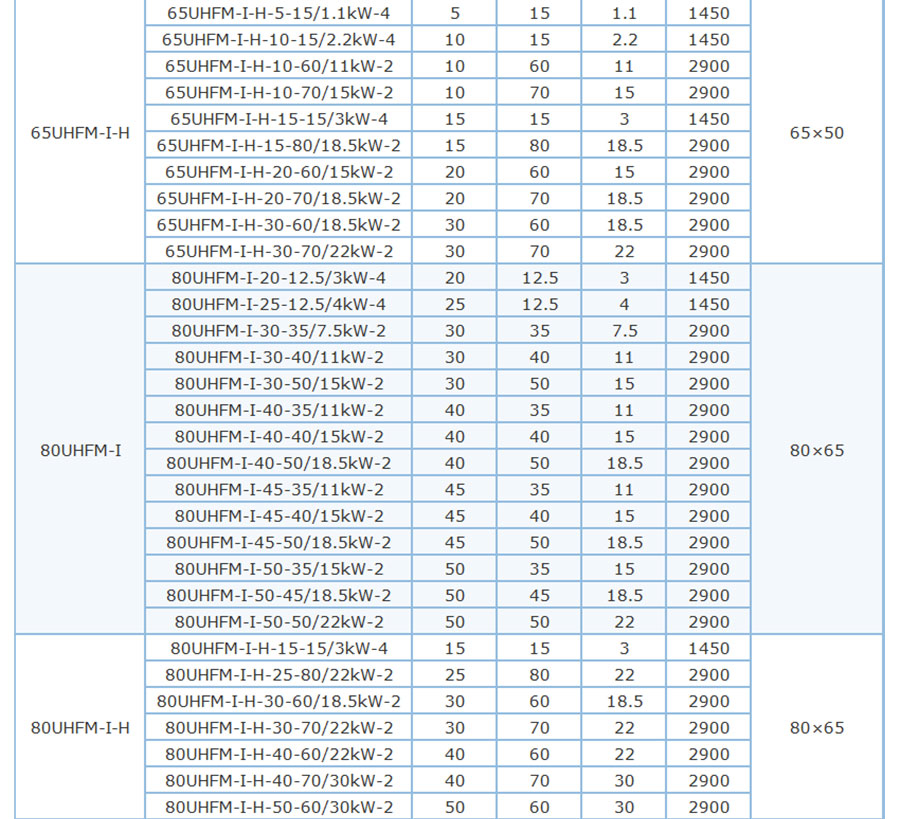

Model: 65UHFM-I-H-20-60/15KW-2

Pump inlet diameter: 65 mm

Pump outlet diameter: 50 mm

Flow rate: 20 m³/h

Head: 60 m

Power: 15 KW

Material: UHMWPE+QT

We can provide pump selection for free.

Please send the liquid name, temperature, density, viscosity, and other requirements.

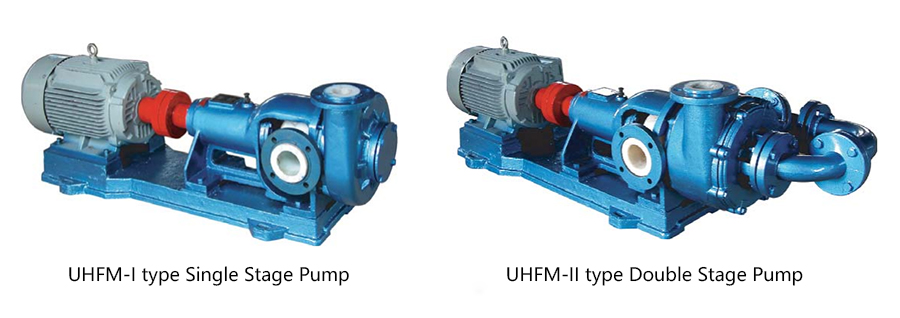

UHFM-I series single stage pressure filter press and feeding pump leak free, corrosion-resistant and wear-resistant pump is a new type of lining type rear suction (shaft seal position in the same direction as the inlet) corrosion-resistant and wear-resistant pump.

The main features are:

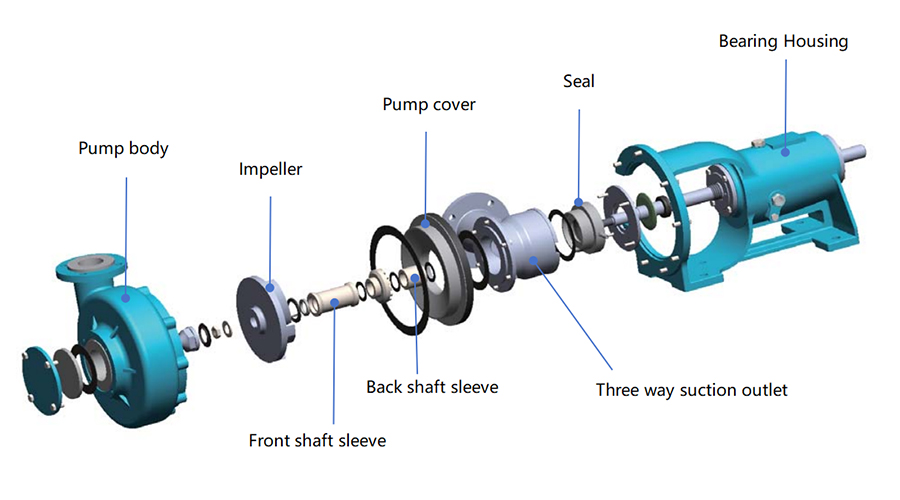

1. The pump inlet is in the same direction as the shaft seal, and the shaft seal is in a negative pressure environment, so it will not leak, overcoming the fixed problem of easy damage to the original corrosion-resistant and wear-resistant pump and easy leakage of the shaft seal.

2. Widely applicable: This pump is equipped with various interchangeable lining materials, which can be used for the transportation of corrosive and abrasive liquids and slurries with various chemical properties. Moreover, the spare parts of different materials have good interchangeability, making it extremely convenient for users to adjust.

3. Low operating costs: There are two main factors contributing to this. Firstly, the pump cover and suction port, which are vulnerable parts, adopt a separate structure with independent corrosion-resistant and wear-resistant components, making replacement convenient and more economical. The second is that the sealing of the pump does not use a back impeller for pressure reduction, which saves the consumption of shaft power and energy.

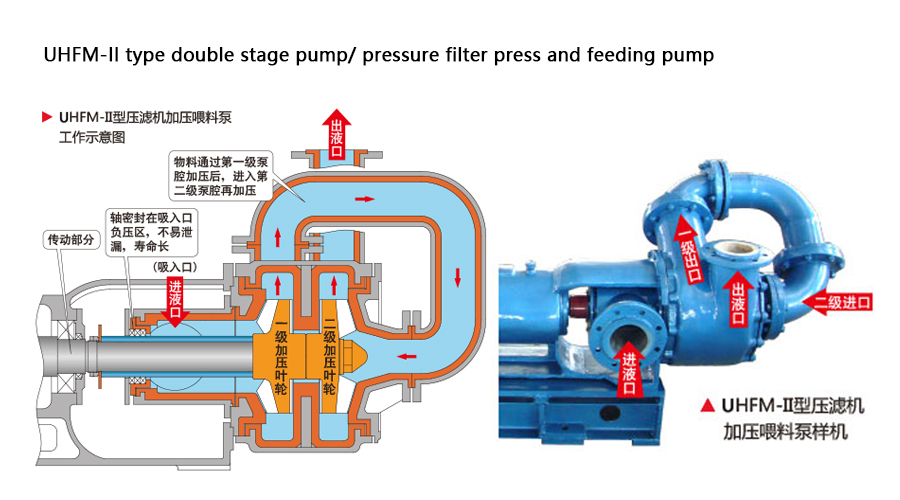

4. Another advantage of the UHFM-II two-stage corrosion-resistant and wear-resistant slurry pump is its good wear resistance, as it achieves higher pump outlet pressure with a lower single impeller linear velocity, thus overcoming the disadvantage of increasing impeller linear velocity to increase pressure in single-stage slurry pumps, which leads to increased wear of impellers and pump casings, effectively improving the service life of wear parts such as impellers and pump covers.

5. The UHFM-II two-stage corrosion-resistant and wear-resistant pump, due to its high pressure, has good filtration effect and low water content in the filter cake when used with a high-pressure filter press, overcoming the disadvantage of insufficient pump pressure when used with a filter press.

Application

1. This series of pumps can transport various corrosive and non corrosive clear liquids and slurries at temperatures up to 100 ℃, or be used as pressure feeding pumps for various filter presses, such as filter press pumps or process pumps for wet smelting processes of non-ferrous metals such as zinc, copper, cobalt, nickel, manganese, slurry conveying pumps for mining selection and non-metallic mineral processing (titanium dioxide, kaolin, etc.), sludge and waste residue conveying pumps for environmental protection industries, and filter press pumps or pressure conveying pumps for other chemical, dye, pharmaceutical, and food production processes.

2. Posts that operate under long-term pressure (high pump outlet pressure) to transport corrosive media, such as pressure spray pumps and pressure flushing pumps in flue gas desulfurization and atmospheric treatment.

3. Positions that are prone to leakage when other pumps transport media.

4. This pump has two series: single-stage and two-stage, which can meet the needs of positions that require low flow and high pressure transportation of corrosive slurry.

Not applicable for positions where the liquid level at the suction port is below 0.5m from the pump position or where the negative pressure at the suction port is too high.

For more parameters waiting for you to learn, please contact us via email 18205509969@139.com.

Contact: NEIL

Phone: 86-18205509969

E-mail: 18205509969@139.com

Add: 118, Building 3, Tianrun City Phase II, Tianchang City, Anhui Province. China