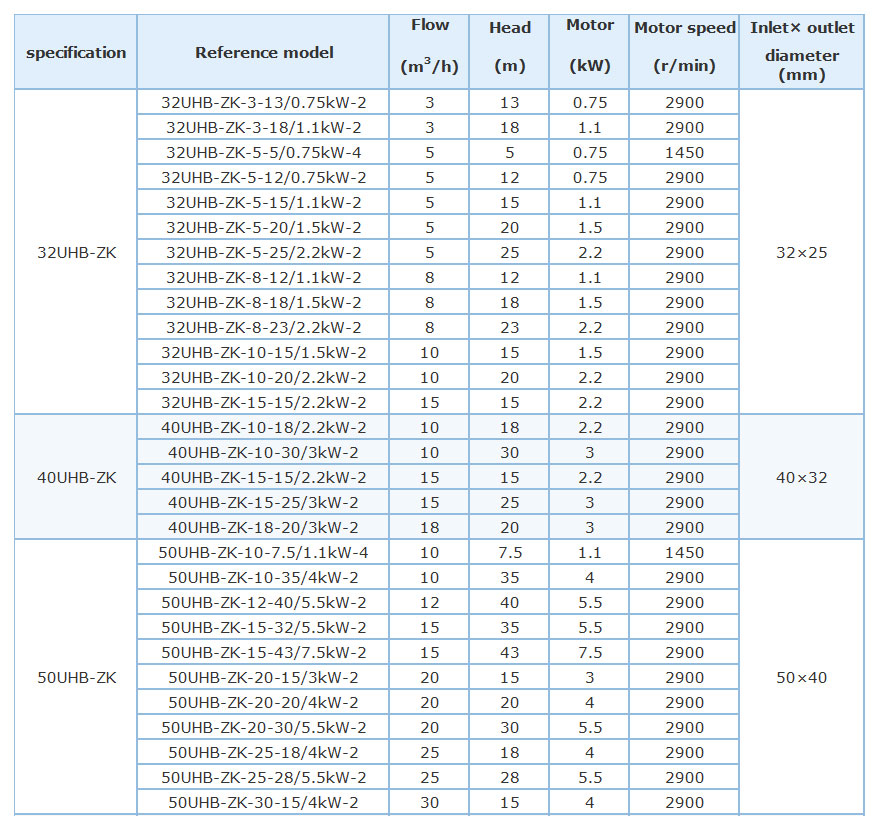

Model: 50UHB-ZK-15-30/5.5KW-2

Pump inlet diameter: 50 mm

Pump outlet diameter: 40 mm

Flow rate: 15 m³/h

Head: 30 m

Power: 5.5 KW

Material: UHMWPE+A3

We can provide pump selection for free.

Product Introduction

UHB-ZK series corrosion-resistant and wear-resistant pump is a single-stage single-suction cantilever centrifugal pump, and the flow parts are made of steel-lined ultra-high molecular weight polyethylene (UHMWPE). The material is a new generation of corrosion-resistant and wear-resistant engineering plastics for pumps in the world, and its outstanding advantage is that it has excellent wear resistance and impact resistance (especially low-temperature impact resistance) among all plastics. Creep resistance (resistance to environmental stress cracking) and good corrosion resistance.

The significant features of the pump are: multi-functional, that is, one pump can adapt to a variety of different working conditions, such as conveying acid, alkaline liquid or slurry; various corrosive slurries in the smelting industry; all kinds of dilute acids in the sulfuric acid industry; All kinds of sewage in the environmental protection industry. The pump is resistant to both corrosion and wear and tear and can be used in a wide range of applications.

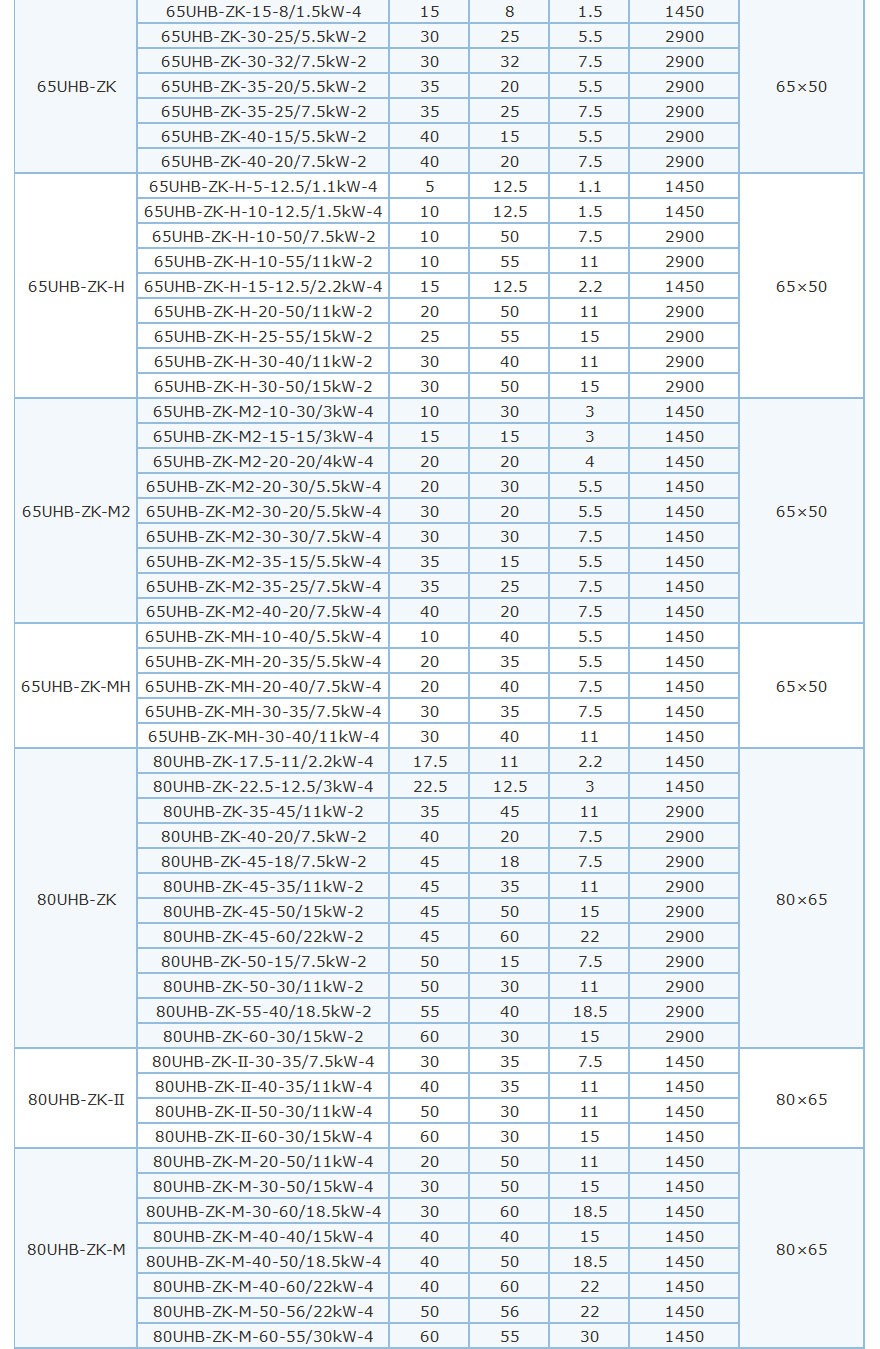

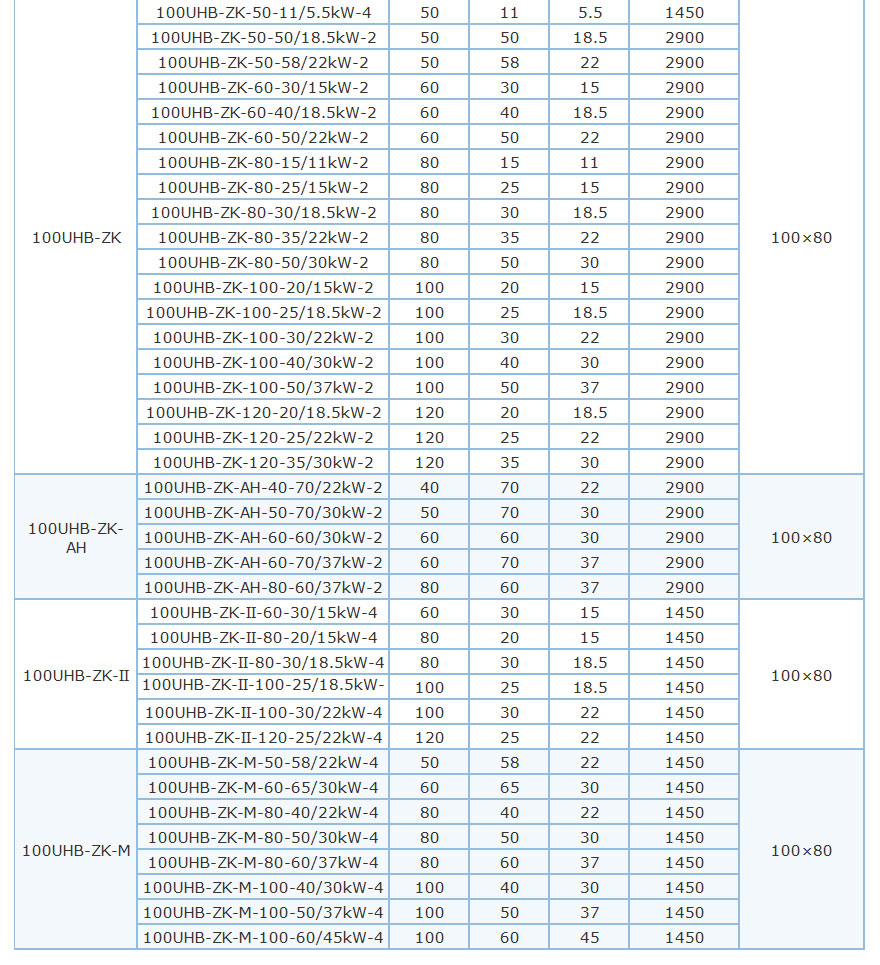

Technical Parameters & Applications

Brief description of the main technical performance

1) Model: UHB-ZK series corrosion-resistant and wear-resistant pump

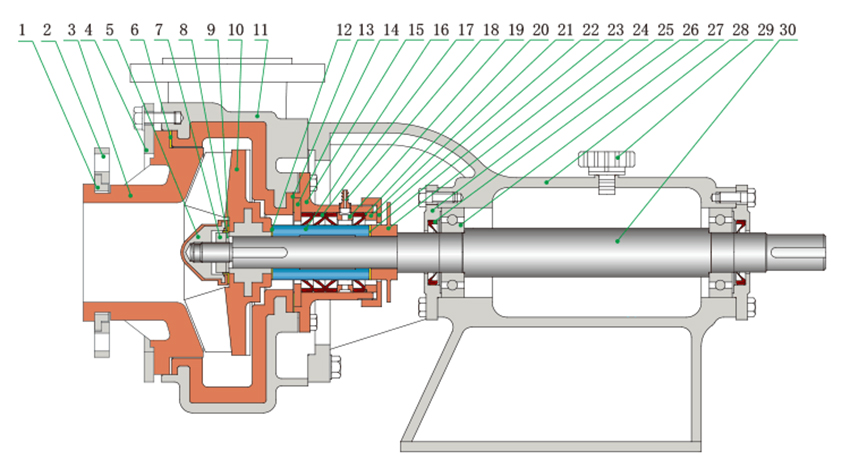

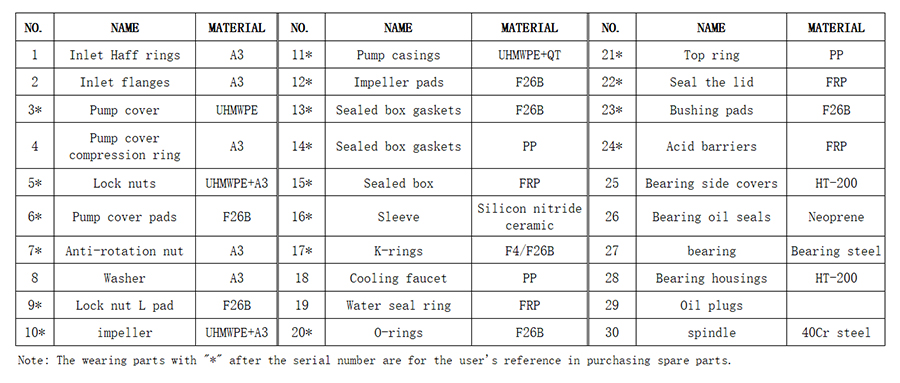

2) Structure and characteristics:

(1) Corrosion-resistant and wear-resistant, one pump is multi-purpose, and acid and alkali clear liquid slurry are applicable.

(2) The pump body is steel-lined ultra-high molecular weight polyethylene structure, the lining thickness is 8~20mm, the pump applies tortoiseshell mesh lining technology, compared with other similar pumps, it has the advantages of good thermal deformation resistance of the lining layer, crack resistance, anti-falling off, and high service temperature.

(3) There are two types of impellers: split type and closed type, which can be selected according to the condition of the medium.

(4) Seal: K-type power seal, G3, G4 mechanical seal.

3) Applicable medium: sulfuric acid with a concentration of less than 80%, nitric acid with a concentration of less than 50%, hydrochloric acid and liquid alkali of various concentrations, suitable for both clear liquid and slurry.

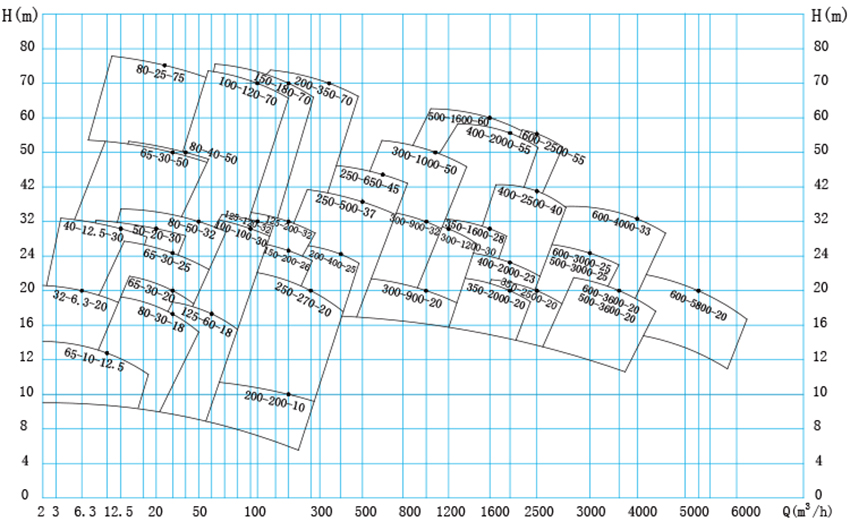

4) Main technical parameters: operating temperature -20°C~90°C, inlet diameter 32~350mm, flow rate 5~2600m3/h, head within 80m.

Extremely wide range of applications

1) Phosphorus sulfate fertilizer industry: transportation of dilute acid, mother liquor, sewage, seawater, fluorosilicic acid containing silica gel, phosphoric acid slurry and other media.

2) Non-ferrous metal smelting industry: especially suitable for lead, zinc, gold, silver, copper, manganese, cobalt, rare earth and other hydrosmelting of various acids, corrosive slurry, slurry (with filter press) electrolyte, sewage and other media transportation.

3) Chemical and other enterprises: all kinds of sulfuric acid, hydrochloric acid, alkaline, oil clear liquid or slurry positions. Production of titanium dioxide and iron red powder, production of various dyes and pigments, processing of non-metallic minerals and other industries.

4) Chlor-alkali industry: hydrochloric acid, liquid alkali, electrolyte, etc.

5) Water treatment industry: pure water, high-purity water, sewage (leather sewage, electroplating sewage, electronic sewage, papermaking sewage, textile sewage, food sewage, domestic sewage, pharmaceutical sewage, etc.).

6) Iron and steel enterprises: sulfuric acid, hydrochloric acid posts of pickling system, sewage with impurities.

7) Wet desulfurization circulating pump: It can be used for alkaline, acidic and corrosive positions at the same time.

8) Transportation of corrosive liquids and coal slurry in the coal industry and coal chemical industry; Coal washing and preparation with pumps.

Schematic diagram of the structure of the pump without auxiliary impeller

For more parameters waiting for you to learn, please contact us via email 18205509969@139.com.

Contact: NEIL

Phone: 86-18205509969

E-mail: 18205509969@139.com

Add: 118, Building 3, Tianrun City Phase II, Tianchang City, Anhui Province. China