Mechanical vapor recompression (MVR).

Mechanical vapor recompression technology (hereinafter referred to as MVR) uses the secondary steam and its energy generated by the evaporation system itself to upgrade the low-grade steam into a high-grade steam heat source through the mechanical work of the compressor. This cycle provides heat to the evaporation system, thereby reducing the need for external energy.

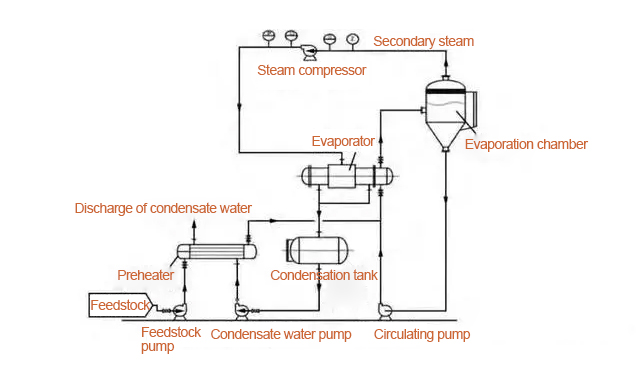

▲Schematic diagram of MVR evaporation

In this system, the heat source in the preheating phase is provided by the steam generator until the material begins to evaporate to produce steam.

The secondary steam produced by the material after heating is compressed into high-temperature and high-pressure steam by the compressor, and the high-temperature and high-pressure steam generated here is used as the heating heat source, and the material in the evaporation chamber is continuously evaporated by heating, and the high-temperature and high-pressure steam through the compressor is cooled into condensate, that is, the treated water.

As the heat source of the whole system, the compressor realizes the conversion of electrical energy to heat energy, and avoids the dependence and ingestion of external steam in the whole system.

MVR system equipment composition

It is not difficult to see from the MVR evaporation process that the MVR evaporation system is composed of various equipment connected in series, and the equipment should be skillfully matched in thermodynamics and heat transfer to achieve the best effect of the whole system.

The main devices in the system are the following 4

1. There are two main types of compressors

roots compressor and centrifugal compressor.

Roots blowers are often used to compress steam with a small flow rate, and belong to the positive displacement compressor, which provides small air volume and large temperature rise, and is suitable for materials with small evaporation and high boiling point.

The centrifugal compressor is a differential pressure fan, which provides small differential pressure, large flow, small temperature rise, uniform exhaust, and no pulse in the air flow, which is suitable for materials with large evaporation capacity and small boiling point rise.

Overall, centrifugal compressors are more stable than roots compressors, but centrifugal compressors sometimes have surge, which can lead to compressor instability.

2. an evaporator

The types of evaporation treatment devices are generally divided into two types: rising film evaporation and falling film evaporation. It is mainly selected according to the characteristics of the treatment and energy consumption. At present, the domestic main use of falling film evaporation method.

3. Heat exchanger

In the MVR heat pump evaporation process, the heat exchangers used are mostly intermural heat exchangers. In this type of heat exchanger, the hot and cold fluids are not in direct contact but are transferred through the walls.

The types of wall heat exchangers commonly used in production are: tubular heat exchangers, corrugated heat exchangers and spiral heat exchangers.

4. Gas-liquid separator

The gas-liquid separator is a place that provides the separation of materials and secondary steam. Its main function is to aggregate the solution in the mist into droplets, and separate the droplets from the secondary steam. It is worth mentioning that the design of the separator should fully consider the evaporation capacity, evaporation temperature, material viscosity, separator level and other factors.

Technical advantages of MVR

1. Compared with the traditional evaporation system, the MVR system only needs to introduce raw steam as a heat source when starting, and when the secondary steam is generated, the system will operate stably, and there will be no need for an external heat source, and the energy consumption of the system is the energy consumption of the compressor and various pumps, so the energy-saving effect is quite significant.

2. The energy consumption of the MVR evaporator system is mainly the power consumption of the compressor, the operating cost is greatly reduced, the operation and maintenance cost is low, and the hidden danger in safety is low and the operation is simple because the system does not need industrial steam.

3. Under the same evaporation treatment capacity, the floor space required by MVR evaporator is much smaller than that of traditional multi-effect evaporation equipment.

Common technical problems in MVR treatment of highly saline wastewater

Although MVR technology has played a good role in the treatment of high-salt wastewater, there are still some technical problems in operation that affect the operation effect.

1. System fouling problem

The fouling of the heat exchanger wall is one of the main reasons for the reduction of the evaporation efficiency of the system, which is mainly due to the use of secondary steam as the heating heat source, and the scaling and coking will reduce the heat transfer effect and the evaporation per unit time, which will reduce the available amount of compressed secondary steam and have a more obvious impact on the production capacity.

Due to the special nature of MVR evaporators, it is common to not be able to clean the equipment on time, which is one of the reasons for the instability of production capacity.

2. Temperature rise

The temperature rise problem in MVR systems is an important factor in saline wastewater treatment applications. When MVR technology is used to treat high-concentration salt-containing wastewater, due to its high concentration and large boiling point rise, the corresponding steam compressor needs to increase the temperature to overcome the influence of the boiling point increase, which puts forward higher requirements for the compressor and significantly increases the system energy consumption.

The results show that the reasonable temperature rise range is 8°C~20°C using MVR evaporation technology. If the boiling point rises above 18°C, the MVR technology loses its advantage.

3. The selection and matching of material physical properties to MVR

Due to the different sources of industrial wastewater, MVR needs to be selected according to the physical properties of different materials. The analysis of material characteristics mainly includes: the composition of the material; whether the material is accompanied by crystallization precipitation during the evaporation process; Viscosity, specific heat, density and boiling point of the material.

The parameters of a single material can be obtained by consulting the relevant tables, but the industrial high-salt wastewater is mostly a mixed type of material liquid, and its relevant data can only be estimated by simulation, so accurate analysis and calculation of the physical properties of the material is the key factor to ensure the normal operation of the MVR device.

Generally speaking, for materials with a large increase in boiling point temperature, MVR single-effect evaporation is generally used; Forced circulation is required for highly concentrated materials to prevent coking due to the slow flow rate of the material; Heat-sensitive materials need to stay in the evaporator for as short a time as possible.

To sum up, the current evaporation technology is widely used, but at the same time, there are also problems such as high energy consumption, high operating cost, easy fouling and blockage, so we must focus on high efficiency and energy saving, and multi-effect evaporation MED and mechanical vapor recompression evaporation MVR are recommended high-efficiency and energy-saving technologies.

Among them, the one-time investment of MVR evaporation unit is relatively large and the energy consumption is low, but with the continuous improvement of technology and production process of domestic steam compressors, the price is also declining; The increase in the number of multi-effect evaporation devices will increase the investment in multi-effect evaporation devices, but the energy consumption can also be reduced to a certain extent.

Therefore, whether it is MVR evaporation device or multi-effect evaporation device, there are certain relative advantages, and it is necessary to make a multi-faceted comparison according to applicability, investment, operation, consumption, labor and land occupation.

Contact: NEIL

Phone: 86-18205509969

E-mail: 18205509969@139.com

Add: 118, Building 3, Tianrun City Phase II, Tianchang City, Anhui Province. China