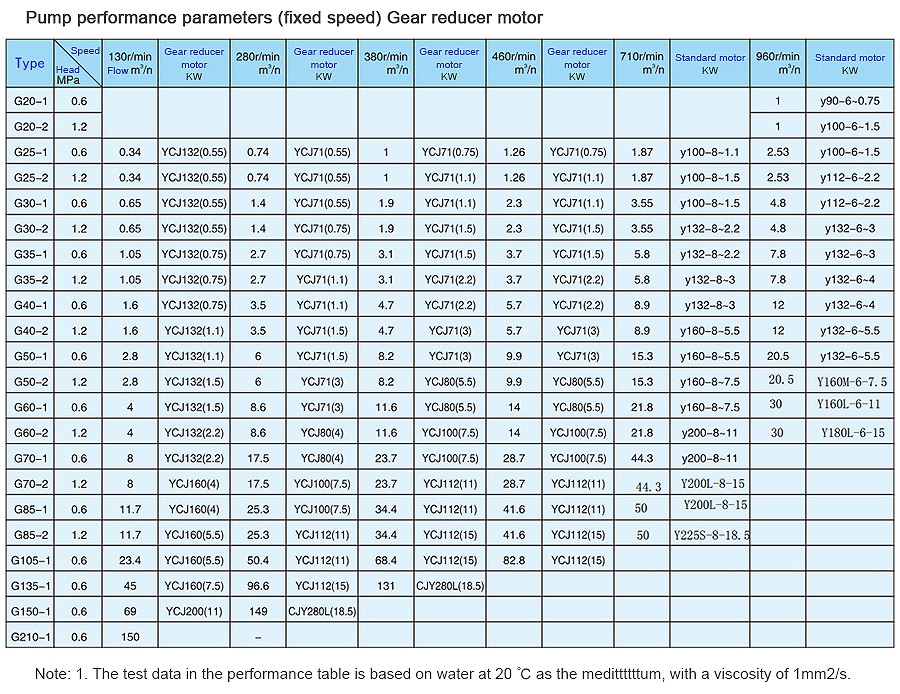

Model: FG35-1BP

Pump inlet diameter: 65 mm

Pump outlet diameter: 50 mm

Flow rate: 8 m³/h

Head: 60 m

Power: 4 KW

Speed: 960 r/min regulation

Material: Cast iron/SS304/SS316

We can provide pump selection for free.

Please send the liquid name, temperature, density, viscosity, and other requirements.

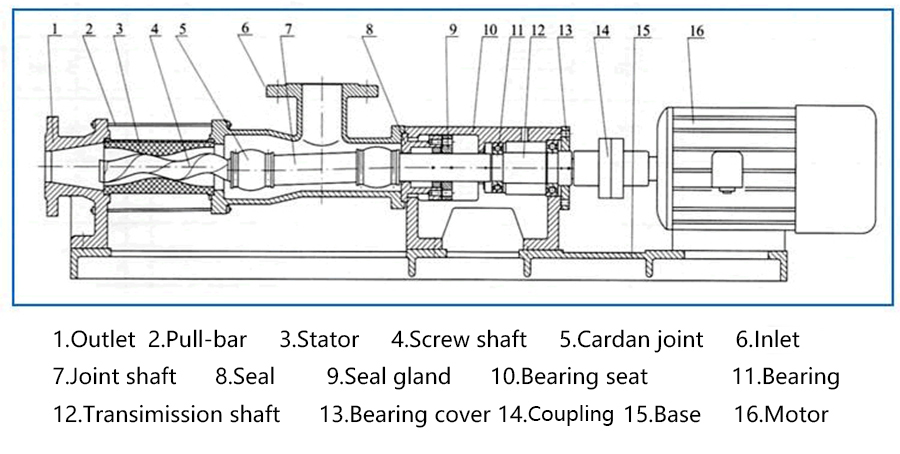

FGP stainless steel single screw pump with variable frequency motor for speed regulation belongs to rotary displacement pump, which relies on the mutual engagement of screw and liner to produce volume changes in the suction and discharge chambers to transport liquids. It is a closed screw pump with internal meshing, and the main working components consist of a liner (stator) with a double headed spiral cavity and a single headed spiral screw (rotor) that meshes with it inside the stator cavity. When the input shaft drives the rotor to rotate around the center of the stator through the universal joint, the stator rotor pair continuously meshes to form a sealed chamber. These sealed chambers move at a constant speed in the axial direction, conveying the medium from the suction end to the discharge end through the stator rotor pair. The medium sucked into the sealed chamber flows through the stator without being stirred or damaged.

ZOOANY-Precautions for using G-type single screw pump

1. Before using a single screw pump, the direction of operation must be determined and must not be reversed.

2. Single screw pumps are strictly prohibited from operating without a medium to avoid damage to the pump.

3. For newly installed or shut down single screw pumps, they cannot be started immediately, an appropriate amount of lubricating fluid should be injected into the G-type single screw pump body first, and then the pipe clamp plate should be rotated a few times before starting.

After conveying high viscosity or media containing particles and corrosiveness with a single screw pump, it should be rinsed with water or solvent to prevent blockage and avoid difficulty in starting next time.

5. Single screw pumps should queue up for liquid accumulation in winter to prevent freezing and cracking.

During the use of a single screw pump, lubricating oil should be regularly added to the bearing box. If seepage is found at the shaft end, the oil seal should be promptly treated or replaced.

If any abnormal situation occurs during the operation of the single screw pump, it should be stopped immediately to check the cause and eliminate the fault.

Contact: NEIL

Phone: 86-18205509969

E-mail: 18205509969@139.com

Add: 118, Building 3, Tianrun City Phase II, Tianchang City, Anhui Province. China